- Articles

- |

- Tech Library

- |

- Catalogue

- |

- About Us

- |

- Contact us

Bitum develops, manufactures and markets its leading products – the most advanced of their kind. For more than 70 years, Bitum has led the market with sealing products for all applications: bitumen enhanced with polymers, bitumen mastic applied by spray, standardized bitumen sheets, acrylic sealing products, silicones, polyurethanes and cementitious materials.

Bitum provides various solutions for thermal insulation – notably, BTI: Innovative insulation consisting of polyester fibers and aluminum. In addition, Bitum holds a line of acoustic insulation products based on polyester fibers.

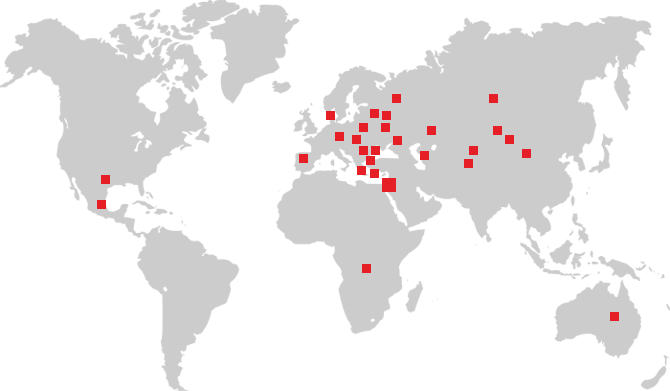

Alongside these prime products, the company manufactures and markets products for the paving industry, including bituminious emulsions. Bitum exports its fine products to a vast number of countries in both Western and Eastern Europe, USA, South Africa, Australia and many more, for use in public and private projects.

These have made Bitum a well-established and respected company, leading the market in its field and taking part in worldwide projects.

The train tunnel in Afula, Israel, 900-meter length, with a bow cross section, has been sealed successfully with FLEXIGUM – two component sealing system, produced by Bitum.

total area of the project : 50,000 m²

Flexigum is performed through two-component elastomeric sealing material of the highest quality, to be applied by spraying.

Main | Bitum Ltd:

Haytzira 4 Str.

Haifa Bay 2611101

PBOX 10175

Tel.: +972-4-8416217

Fax: +972-4-8416219

Bitum Phone: 1-800-30-20-60

Sales and Distribution:

Nachshon 22 Str.

Petach Tikva

Tel.: +972-3-6227123